The Path to Overcoming Crisis: Finding Overall Optimum Solutions for a Heap of Challenges

Fujimoto Takahiro, Professor, Graduate School of Economics and Manufacturing

Management Research Center, University of Tokyo

Key points

- Issues include sustainability, digitalization and internationalization

- The discourse around the decline in the Japanese manufacturing industry and the praise for EVs is superficial

- The challenges are intertwined in complicated ways and Japanese industry is evolving

Prof. Fujimoto Takahiro

What kind of age will the 2020s be in the evolution of industry? The decade began with the global COVID-19 pandemic, the effects of which are certain to be prolonged, but the long-term industrial phenomena include measures to counter global warming, a series of floods and earthquakes, digitalization, US-China friction, and a shrinking real economy at a time of infections. To complicate matters, these issues are interlinked in complex ways. We live in complicated times in the true sense.

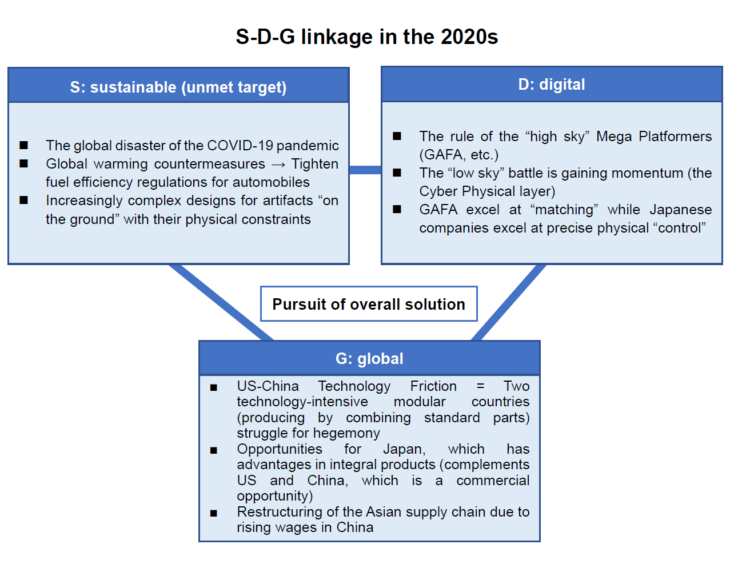

These issues can be summed up as S for sustainability=crisis, D for digitalization, and G for globalization. The SDGs refer to the 17 Sustainable Development Goals presented by the United Nations in 2015 (the unfinished issues), but in the 2020s, industrial people and policymakers will have to think through the even greater S-D-G linkage, which also includes the Sustainable Development Goals. The overall optimum solutions that seek to solve these enormous simultaneous equations will be the effective solutions.

But on the other hand, short and attractive phrases spread rapidly on the Internet and impact even approval ratings and stock prices. As a result, industry leaders and the Fourth Estate are tempted to impart large numbers of sound bites while ignoring inconvenient constraints and picking apart the confusing simultaneous equations one by one. A single mistake leads to a barrage of individual solutions with serious omissions.

There are a good number of statements with such questionable reasoning. For example, the discourse on the decline of Japanese manufacturing, the praise for electric vehicles (EVs), and the mistaken belief that Japan is lagging behind Industry 4.0 (a misunderstanding that confuses German predictions for the 2020s with the realities of the 2010s).

The discourse on the decline of the Japanese manufacturing industry has repeatedly come and gone over the past thirty years. But, in the end, the total value added for the Japanese manufacturing industry at the end of the Heisei era in 2019 was over 100 trillion yen, which is almost no reduction when compared to the start of the Heisei era in 1989. Divided by about ten million workers, value-added productivity is about eleven million yen. Supposing that non-manufacturing industries also achieved such productivity, Japan’s GDP would exceed 700 trillion yen instead of the present 500 trillion yen. This is the result of the “Thirty Years’ War” of the Japanese manufacturing industry, which has rebounded from the severe handicap of an initial wage difference of about twenty times that of China, by means of production innovation that has increased physical productivity fivefold in five years. Much of the discourse on the decline is missing statistical analysis, field observation, and theoretical discussion.

The praise for EVs also confuses purpose and means with regard to the main purpose of preventing global warming. There is no overall solution unless everything is taken into consideration such as the limits on energy density in the current generation of lithium-ion batteries, or weaknesses such as ignition/deterioration/charging times, the issues of materials procurement and cost, and the political motives of each government. We cannot ignore the fact that current EVs emit CO2 at the stages of power generation and manufacturing. The Chinese government will develop EVs based on the industrial-political judgment that catching up with the advanced nations’ technology is easy in the case of EVs, but there are limits on global warming countermeasures under the current system where coal-fired power generation is common.

The worldwide market share for pure EVs without an internal combustion engine is about 2% of the market for new cars (2018), or less than 1% based on vehicle ownership and total mileage. The full-scale spread of the anticipated next-generation all solid battery is forecast for around 2030, at which time, the EV adoption rate will be 10–20% according to many experts. Each national government intends to boost policies for take-up, but it is not easy to find an overall solution. If subsidies are stopped, there may be a wave of bankruptcies among start-up enterprises, and even if they hurriedly resume operations, they will be confronted with the problem of being financially unsustainable.

Based on the fundamental objective of preventing global warming, it is necessary to cut the total value of “global kilometers traveled by electric motor x CO2 emissions per kilometer traveled” and the “global kilometers traveled by internal combustion engine x CO2 emissions per kilometer traveled.”

If the latter currently accounts for more than 99% of emissions, and it takes more than ten years for EV to become widespread, it will be vital for the persons responsible for measures to counter global warming in the 2020s to find an overall solution while simultaneously advancing the following three topics: (1) Continue technical innovation to cut CO2 emissions per kilometer for the internal combustion engine, which still accounts for the majority of vehicles; (2) Accelerated development of attractive electric vehicles and EVs accepted by the market; and (3) reduce total CO2 emissions from thermal power generation.

The spread of EV is a long-term issue that will extend throughout the 2030s. In the transitional period of the 2020s, the Japanese automobile industry will be the main protagonist reducing CO2 emissions from automobiles by maintaining its hardware advantage, which includes point (1) above, while an overall solution will require the kind of general mobilization described above. The objective is to minimize the problem of warming, and it is important to use calm arithmetic and scientific reasoning. The black-and-white dualism of “pro-EV or anti-EV” will not produce an effective overall solution to the problem of global warming in the 2020s.

Finally, I would like to take a look at the Kofu Plant at Panasonic Smart Factory Solutions as a typical example of a prominent domestic plant that explores and develops overall solutions within the S-D-G linkage.

Since semiconductor mounting machines, which is the main product, require ultra-high performance due to miniaturization, optimum design according to the specifications of individual customers is essential (D). The Japanese hub has a comparative design advantage with integral architecture that is compatible with the coordination-rich manufacturing sites (genba) created in postwar Japan (G). On the other hand, due to the emergence of the low-wage powerhouse of China in the 1990s, and the rising wages in China since 2005, Japan has triangular supply chains in Asia, which have hubs for producing parts and finished goods in Japan, China and ASEAN (G).

Japan did not close its factories because of curfews and companies have taken defensive measures to prevent intra-plant infections (S). There are zero infections at the Kofu Plant due to temperature measurements, hand sanitizers, masks, social distancing, and commuting by private cars. Because of its advanced hygiene management in normal times, the plant has the role of a mother factory to its overseas factories in terms of its ability to prevent infections (G).

Component hubs in China were temporarily closed in January 2020, and in March 2020 factories closed at several ASEAN hubs, but due to its rapid substitutive production, the production lines at the Kofu Plant have not stopped. The supply chains will continue if the genba recovers or substitutive production starts within the item’s inventory days. The experience accumulated at the time of the “visible disasters” of the past, such as earthquakes, has also been applied to this “invisible global disaster” (S).

On the other hand, the miniaturization of semiconductors, which had temporarily slowed down, accelerated at the end of the 2010s due to groundbreaking laser technology, and growing digital demand for AI, the 5G high-speed communication standard, and IoT (D). In around March 2020, the original design manufacturers (ODM) in Asia, which had been cautious due to the global recession and US-China friction, took the plunge and expanded production and capital investment (D).

Since reliable deliveries are more important than cost during the current COVID-19 global pandemic, leading Japanese companies whose supply chains continue to move are raising their profiles (G). In fact, since March, the Kofu Plant has received large orders from overseas and will continue to operate at full capacity even during the period of emergency declaration.

Digital manufacturing efforts are also accelerating (D). A team of multi-skilled workers monitor Cyber Physical Systems (CPS), which integrate and analyze the information space and the real world, while taking on the challenges of complex, variable-mix variable-volume production, which is oriented toward a Japanese style of digital manufacturing that differs from both China and the United States (D, G).

Industry in Japan is evolving in a form where S-D-G is intricately intertwined. Companies and the genba pursue overall optimal solutions for S-D-G. If you observe these things in isolation, the direction of industrial evolution in the 2020s, where measures to counter disasters, infection, and global warming (S), low sky battles using CPS (D), and US-China friction (G) are linked, does not come into view.

Translated by The Japan Journal, Ltd. The article first appeared in the “Keizai kyoshitsu” column of The Nikkei newspaper on January 7, 2021 under the title, “Kiki-kokufuku e no Michisuji:Sanseki kadai no zentai saiteki-kai sagure (The Path to Overcoming Crisis: Finding Overall Optimum Solutions for a Heap of Challenges).” The Nikkei, January 7, 2021. (Courtesy of the author).

Keywords

- Fujimoto Takahiro

- University of Tokyo

- S-D-G

- sustainability

- digitalization

- internationalization

- manufacturing

- industry

- electric vehicles

- EVs

- emissions from automobiles

- global warming

- Panasonic Smart Factory Solutions

- Kofu Plant

- COVID-19

- US-China friction