Post-Coronavirus World: Companies Should Continue to Disperse Production and Procurement

Todo Yasuyuki, Professor, Waseda University

Key points:

- Bringing manufacturing back to Japan comes with risks

- Don’t fall behind the expansion of global value chains

- Build strong ties with mutual help with partners abroad

Prof. Todo Yasuyuki

The disorder caused by the spread of COVID-19 continues. Nonetheless, we need to look toward the “Post-Coronavirus world” amid this confusion. This paper is a consideration of what supply chains and value chains Japan ought to build in the world after the coronavirus crisis.

Value chains refer to networks of economic activities that generate value, including upstream R&D and design as well as downstream marketing and data analysis, and that exist in addition to the supply chains for materials and components.

The Japanese government is already taking action. The spread in China disrupted the procurement of parts, components and materials from China. This is why the government is now going to provide subsidies to companies that decide to bring their production sites back to Japan or move them to Southeast Asia. It is an attempt at revising China-dependent supply chains.

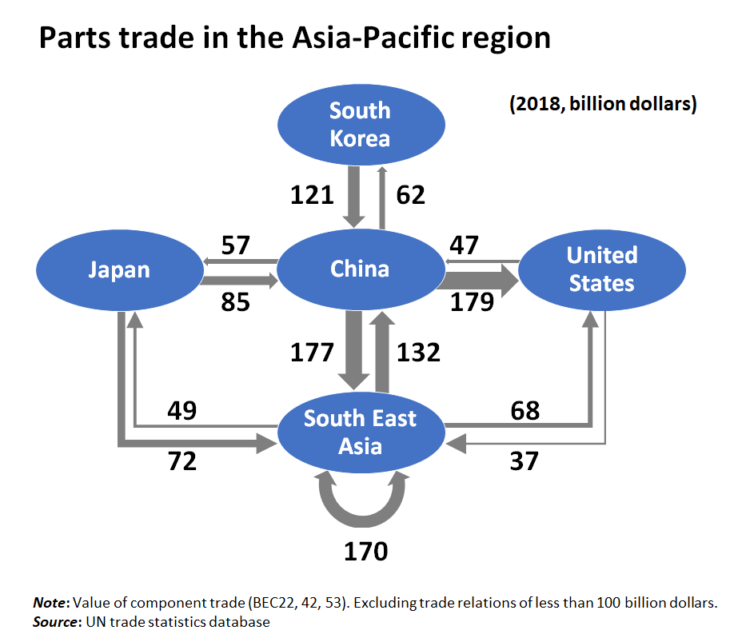

The figure shows the parts trade in the Asia-Pacific region in 2018. It is true that Japan is remarkably dependent on China. This is why it appears that the disruption of the component supply from China due to COVID-19 is a good opportunity to bring production back to Japan or move it to Southeast Asia.

However, the spread of infectious diseases is not the only threat to supply chains. Another major risk is the disruption of supply due to earthquakes, floods, and other natural disasters. This is what Japan experienced with the Great East Japan Earthquake.

The Nankai Trough earthquake, predicted to occur in the near future, will likely cause massive damage to key industrial agglomerations on the Japanese Pacific coast. When that happens, companies with many part and component suppliers that have returned to the affected areas in Japan will not be able to substitute those suppliers and will suffer big damage.

The most basic approach to risk management is dispersion. If companies disperse production sites and suppliers, they can switch from a supplier damaged by an economic shock to another one and keep up production. As such, reducing dependence on China is an effective way to counter the risks, but the solution is not bringing manufacturing back to Japan but to move or expand to other countries. Moreover, since Japanese companies are already clustered in Southeast Asia, moving to the middle income countries in Southeast Asia will not constitute a real dispersal.

Robotization has reduced the share of personnel expenses in the manufacturing industries in recent years, decreasing the need to move overseas production sites to developing countries where wages are low. This is why supply chains should also be expanded to advanced countries and regions like Europe, North America, South Korea, Taiwan, and Australia. For example, the total value of the Japan–US part trade is 85.1 billion dollars in 2018, which is smaller than the 226.1 billion dollars between the US and China, so there is much room for expansion.

Furthermore, not only production but also R&D, data analysis and other activities yielding high value added should be developed in advanced countries. This is because new knowledge and information that can lead to domestic innovation can be gained by partnering with local companies in various countries. That is, it is important for us to have a mindset of developing not “supply chains” but “value chains” abroad.

China is already headed in that direction and is diversifying supply chains (see figure). Effectively utilizing the Belt and Road Initiative, China is developing trade relations with South and Central Asia. Diverse and robust supply chains with China as their hub are being built in Asia. Chinese companies have actively conducted joint research with European and North American companies and universities to learn new technologies although these relationships are now affected by the US-China decoupling, and now China has become the world’s biggest source of patents.

Not only this, but China is advertising that it was the first to bring COVID-19 under control and is seeing this as a chance to strengthen its position in global value chains. A good example is their appeal to Italy, which has suffered big damage, to build a “Health Silk Road.” China is not trying to become a hub for Asian supply chains but for global value chains.

Amid such developments, if Japanese companies return to Japan and are left behind by the global value chains, this will decisively deteriorate the economy and make Japan a less-developed country.

Thus, what is needed is not support for bringing manufacturing back to Japan or moving it to Southeast Asia, but broad support for the development of international businesses, particularly those with high value added, not bound by region. For example, it would be effective to support information sharing, participation in trade fairs, business matching, and overseas R&D.

For expansion of production sites to developing countries, official development assistant (ODA) should be utilized. ODA has stimulated direct investment from Japan and helped Japanese companies to build supply chains in East Asia. We should expand ODA to South Asia, Africa, and other regions, stimulating the expansion of Japanese companies there as well.

Having said that, it is probably not enough to diversify supply chains in order to deal with the various risks. This is because, after the spread of COVID-19, as the world economy shrinks, nationalism has erupted in many countries and domestic supply of some products is prioritized while their supply to other countries is stopped.

What will facilitate quick recovery in case of a crisis is mutual assistance. At the time of the Great East Japan Earthquake, supply chain recovery was sped up when affected suppliers received support from their client companies and asked for help from competing companies to maintain part supply to clients.

This support was possible because the companies have had transactions for a long time and trust each other. In exchange for helping their partners when needed, companies will receive help when needed. There is a tacit contract of mutual help that will be terminated if one is betrayed.

Likewise, it should also be possible to prevent supply-chain disruptions in case of a crisis by building trust-based relationships of mutual help with overseas business partners. For example, 3M continued to export medical face masks to Canada and Latin America despite US President Trump’s appeal for 3M to stop. This was likely because of the trust that existed between 3M and its partners.

In Japan, because “keiretsu” is well-established, companies are quite capable of building strong relationships. One good example of keiretsu-type relationships that worked well in a crisis was the mutual help after the Great East Japan Earthquake. Keiretsu-type relationships involve the sharing of information and technologies through technical training and joint research. Also, the relationships often involve shareholding relations. These multi-layered relationships lead to mutual help by linking each other’s interests in various ways.

Therefore, one way to build relationships of mutual help with overseas companies is to forge multilayered connections through technical exchange, joint research and shareholdings. If Japanese companies can support overseas partners amid the ongoing crisis, this could give impetus to mutual help.

China’s actions stand out also here. They are trying to build solid value chains by assisting other countries now.

However, as a country that shares the values of democracy and market economy, is it not Japan’s role to support the countries in Europe and North America that are suffering from the pandemic the most right now? We also owe the United States for their “Operation Tomodachi” during the Great East Japan Earthquake. We also need to support developing countries where the spread is predicted to increase. The Japanese government should engage in international assistance now, also for the sake of Japanese companies’ activities in the post coronavirus world.

Globalization stagnated after the Global Financial Crisis and even declined with the US–China decoupling. Japan can build a prosperous and robust economy by developing diverse and strongly connected value chains in the world after the corona crisis. I hope both the public and the private sectors will be preparing for that now.

Translated by The Japan Journal, Ltd. The article first appeared in the “Keizai kyoshitsu” column of The Nikkei newspaper on 16 April 2020 under the title, “Koronashokku-go no Sekai (II): Kigyo, Seisanchotatsu no Bunsan keizoku wo (Post Coronavirus World (II): Companies Continue to Disperse Production and Procurement).” The Nikkei, 16 April 2020. (Courtesy of the author) [June 2020]

Keywords

- Todo Yasuyuki

- Waseda University

- post coronavirus

- Japan

- China

- Southeast Asia

- supply chains

- value chains

- production sites

- infectious diseases

- disasters

- risk management

- dispersal

- robotization

- global value chains

- ODA

- mutual aid